Rigorous testing is critical in maintaining quality and safety standards within the dairy industry. Processing facilities must verify every batch of raw milk and finished dairy products for microbial content, mineral composition and chemical residues. Regular testing ensures products are safe for consumption, free from harmful contaminants and compliant with regulatory standards.

Microbiological Testing

Dairy products are often at risk of contamination due to their nutrient-rich content, which makes them ideal environments for bacteria to thrive. Microbiological testing in the dairy industry is essential in identifying potential risks in dairy products:

- Preventing foodborne illnesses: Microbiological testing helps protect consumer health by identifying harmful pathogens like Salmonella and E. coli.

- Ensuring product quality: Contamination can lead to spoilage, affecting dairy products’ texture, taste, and shelf life.

- Maintaining regulatory compliance: Food safety regulations mandate microbiological testing to protect public health and ensure dairy products meet national and international standards.

Microbiological dairy industry tests monitor raw milk, in-process products, final products and surfaces. Key products used include Petrifilm™ (3M) for quick enumeration of coliforms, E. coli, yeast/mold, and aerobic plate counts, and ATP Meters such as Hygiena EnSURE for surface cleanliness verification.

Total Plate Count

Total plate count (TPC), also known as aerobic plate count or standard plate count, measures the total number of viable aerobic bacteria in a dairy sample. TPC involves culturing a diluted milk or dairy product sample on a nutrient agar plate. After incubation, lab technicians count the colonies and express the results as colony-forming units per milliliter. A high TPC reading may indicate contamination, poor storage practices or insufficient pasteurization. Total plate count kits can expedite this process.

Coliform Testing

Coliforms are bacteria commonly used as indicators of fecal contamination. Their presence signals that other pathogens may be present and that something has compromised the production environment or product. Labs conduct coliform testing using methods like most probable number (MPN) or membrane filtration to quantify these bacteria.

- MPN: This statistical method estimates coliform levels based on bacterial growth in lactose broth. Gas production indicates a positive result.

- Membrane filtration: This method involves capturing bacteria on a membrane and culturing them on selective media for colony counting.

A positive coliform result requires immediate follow-up to identify the contamination source and prevent potential outbreaks.

Pathogen Testing

Pathogen testing identifies specific harmful microorganisms, including Salmonella spp., Listeria monocytogenes and E. Coli. These bacteria can survive various processing methods and cause serious health consequences. The primary techniques for pathogen detection include:

- Polymerase chain reaction (PCR): PCR rapidly amplifies the DNA of target organisms, making it one of the most sensitive and specific methods available. It allows for high-accuracy early-stage detection.

- Culture methods: These techniques involve growing bacteria on selective media, followed by identification using biochemical tests. Though slower than molecular methods, culture remains vital for determining organism viability and performing antimicrobial resistance testing.

Testing Frequency and Protocols

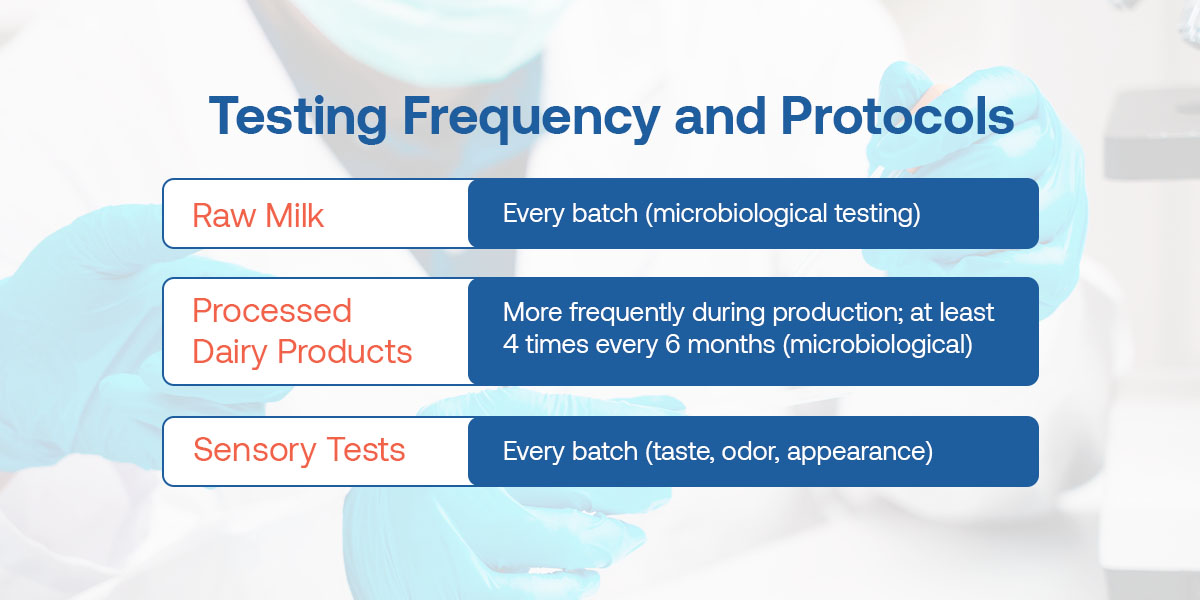

Regular microbiological testing is necessary to maintain dairy product quality and safety. While exact frequencies depend on product type, stage in production and local regulatory requirements, some general practices contained in the Food and Drug Administration’s Pasteurized Milk Ordinance include:

- Raw milk: Microbiological testing, such as TPC and coliform testing, should be performed for every batch to ensure the milk is free from harmful bacteria before processing.

- Processed dairy products: Testing should occur more frequently during production. Producers must sample processed products like cheese and yogurt at least four times every six months to assess microbiological contamination and quality.

- Sensory tests: Facilities should conduct sensory evaluations, including assessments of taste, odor and appearance, for every batch.

Dairy producers must maintain all dairy product quality testing records to ensure traceability and facilitate swift responses in case of contamination at any production stage.

Mineral Testing

Accurate mineral content analysis helps facilities comply with regulatory standards and maintain product consistency. For example, marketers often cite dairy products for their high calcium content — this claim must be verifiable through testing. Mineral testing also supports nutritional labeling and quality control within the dairy industry.

Common Minerals Tested

The following are some commonly tested minerals in dairy products in compliance with food safety regulations:

- Calcium: Calcium is one of the most critical minerals in dairy products. It is crucial for bone health and muscle function in humans, and adequate intake prevents conditions like milk fever in dairy cows. In dairy processing, calcium facilitates coagulation during cheese-making.

- Phosphorus: Like calcium, phosphorus is vital for bone formation, energy production and maintaining cellular functions in both humans and dairy cows. Producers can test phosphorus levels using colorimetric tests or ion-selective electrodes (ISEs).

- Magnesium and potassium: Magnesium and potassium contribute to muscle function and electrolyte balance. Testing these minerals is essential for accurate labeling. Dairy producers can monitor magnesium and potassium levels using colorimetric assays or ion-selective electrodes.

Types of Mineral Testing Kits

Dairy processors can choose from various test kits to test for minerals, depending on the required precision and application environment.

- Colorimetric tests: These kits allow testers to add a reagent to the sample, causing visual color changes that indicate mineral presence and concentration. These tests are often simple, fast and suitable for in-plant quality checks.

- ISE: ISE systems offer more precise and scalable solutions. They measure the electrical potential created by specific ions and are ideal for continuous or high-throughput operations.

Colorimetric methods offer a cost-effective solution ideal for field use, while ISEs deliver enhanced accuracy and better support detailed quality control programs. Most modern dairies integrate both depending on the product and testing stage.

Hydrogen Peroxide Testing

Hydrogen peroxide test kits allow dairy facilities and regulatory bodies to test for hydrogen peroxide in final dairy products. Dairy plants sometimes use hydrogen peroxide in sterilization processes for packaging and equipment. Some parts of the world also use it as a preservative.

Because refrigeration is widely available in the United States, hydrogen peroxide is generally not permitted as a preservative outside of specific applications. Even trace levels of hydrogen peroxide in the final product can compromise taste, shelf stability and regulatory status.

Testing is essential for ensuring hydrogen peroxide levels fall within safe limits and maintain compliance with quality standards and protocols.

Testing Methodology

Most hydrogen peroxide detection kits use endpoint colorimetric analysis. In this method, dairy product samples are mixed with reagents, causing visible color changes that correspond to the concentration of hydrogen peroxide in the sample. A positive hydrogen peroxide test can indicate equipment cleaning issues, inadequate rinsing or improper handling of packaging materials.

Interpreting Results

Acceptable peroxide levels in dairy products are often close to zero. Test results are typically expressed in parts per million (ppm), and the most stringent thresholds range from 0.05 to 0.8 ppm, depending on the regulatory authority and product type. For instance, the Environmental Protection Agency (EPA) stipulates that when manufacturers use hydrogen peroxide solution to sterilize food packaging material, the residue limit should be no more than 0.5 ppm in the food product.

Sanitizing and Environmental Compliance

Sanitizing is a critical step in dairy processing to prevent contamination. It is essential to verify sanitizer concentrations and ensure no chemical residuals remain on surfaces or in product-contact areas. Common tests done in the dairy industry for sanitizing include:

- Titration kits or test strips, such as LaMotte or CHEMetrics, for verifying sanitizer concentrations (peracetic acid, chlorine, quats)

- Oxidation-reduction potential meters to ensure sanitizer strength is active

- Colorimetric test kits for on-the-spot chemical concentration validation

- Sanitizer residue tests

Dairy facilities must also ensure compliance with environmental discharge limits, biological load and chemical oxygen demand. Biological oxygen demand (BOD) is monitored using BOD5 test kits or respirometric systems such as Hach BODtrak. Chemical oxygen demand (COD) is assessed using Hach COD vials and digesters, which are EPA-approved methods. Total suspended solids and volatile suspended solids are measured using gravimetric analysis or Hach-style portable systems.

Comprehensive Testing Solutions for Dairy Producers From AquaPhoenix

Testing in the dairy industry is critical for verifying product quality and safety. From microbiological tests that detect harmful pathogens to mineral and hydrogen peroxide testing that verifies nutritional content and safety, these assessments help dairy producers maintain high standards in their products. Regular testing also supports regulatory compliance and consumer trust.

If you are looking for solutions to help you maintain stringent quality control in your operations, AquaPhoenix Scientific offers a range of reliable dairy industry test kits. Our dependable tools support every stage of your testing workflow. Explore our full range of dairy industry testing products and take your quality control to the next level.