Industrial water conditioning is vital for protecting people, equipment and the environment from harmful contaminants. The water conditioning process involves proactive testing and treatment processes to maintain the proper levels of metals, chemicals and organic solids. With this comprehensive water conditioning overview, you can determine the best water testing and treatment methods for your facility.

What Is Industrial Water Conditioning?

Industrial water conditioning modifies water characteristics to make it suitable for specific industrial applications. It involves thorough testing and treatment processes to reduce or eliminate impurities such as chemicals, suspended solids, volatile organic compounds (VOCs) and dissolved minerals.

Why Water Conditioning Is Necessary

Industrial water testing and treatment are vital for these reasons:

- Health and safety: Water conditioning removes or reduces harmful toxins and pathogens such as Legionella, E. coli, and per- and polyfluoroalkyl substances that could cause illness.

- Compliance: Proactive water testing and treatment can help you comply with regulations such as drinking water standards and discharge limits.

- Process efficiency: Industrial equipment operates more efficiently when it’s free of corrosive or scale-producing contaminants. Removing corrosive contaminants from your systems helps ensure filtration, water flow and temperature control functions work properly. This also prevents repair needs, increasing your equipment’s uptime so you can keep operations on schedule.

- Equipment protection and uptime: Water treatment also protects your equipment from damage, reducing repairs, maintenance needs and associated costs.

- Environmental protection: Testing and treating your facility’s water helps ensure effluents meet the proper limits for metals, chemicals, organic matter and toxicity.

Regular testing provides the necessary data to help you make informed decisions about your chemical or physical treatments. Proactive monitoring is safer and more cost-effective than reactive maintenance and repairs.

What Industries and Types of Equipment Require Water Conditioning?

Water conditioning is vital for any application involving water in processes such as cleaning, cooling or product manufacturing. The following applications require water testing and treatment:

- Power generation: Power generation systems typically involve equipment such as cooling towers, boilers and feed water systems. Water conditioning prevents corrosion, scaling and fouling.

- Oil and gas: The oil and gas industry uses water for cooling, steam generation and refining. The systems involved in these processes require testing to protect equipment and ensure operational efficiency.

- Food and beverage: The food and beverage industry depends on clean water to ensure consumer health and safety. Water used in food or beverage production must meet strict quality standards, making thorough testing and treatment crucial.

- Dairy: Similar to the food and beverage industry, dairy processing systems require water conditioning for health and safety purposes. Testing water used in cleaning and processing equipment prevents contamination.

- Sugar mills and refineries: Sugar mills and refineries require water testing for various stages in their processing and refining systems.

- Pharmaceuticals: Pharmaceutical manufacturing plants rely on clean, pure water for product efficacy and safety. The Food and Drug Administration sets stringent regulations, and maintaining quality water conditioning processes helps companies meet compliance.

- Textile manufacturing: The textile manufacturing industry uses water for production processes such as washing and dyeing. Water conditioning helps ensure consistent results in these processes.

- Pulp and paper production: Pulp and paper mills use water conditioning to prevent contaminants from interfering with the paper-making process.

- Aircraft and automotive manufacturing: Aircraft and automotive manufacturing industries use water in processes such as parts treatment and cleaning. Regular water conditioning protects equipment and helps ensure consistent results in final products.

- Microelectronics: The microelectronics industry depends on high-purity water for semiconductor manufacturing processes. Water conditioning prevents contamination to ensure high-quality products.

Core Water Quality Parameters

Water testing focuses on these main parameters to help you manage clean, safe water for industrial applications:

Managing Water Hardness

Dissolved minerals like magnesium and calcium can increase water hardness, which can cause scale buildup in industrial equipment such as boilers, pipes and cooling towers. Managing water hardness helps ensure efficient heat transfer, helping your company reduce energy expenses.

Controlling Microbiological Growth

Unmanaged microbiological growth in industrial water can cause microbiologically influenced corrosion and health risks such as Legionella. Thorough testing helps you determine the exact biocide type and concentration your water requires, which is essential for controlling:

- Bacteria

- Algae

- Fungi

- Biofilm formation

Preventing Scale and Corrosion

Chemical exposure or environmental factors can lead to corrosion in your equipment’s metal components. This gradual deterioration alters your equipment’s structural integrity, reduces its effectiveness and leaches metals into your process water.

Mineral deposits can produce scale on your equipment’s metal components, which restricts fluid flow, accelerates corrosion and reduces efficiency by insulating surfaces. Testing these factors can help prevent scale and corrosion in your equipment:

- pH levels: Low pH levels can cause corrosion, and high pH levels can lead to scale buildup. Testing pH levels enables you to proactively treat your water for efficient flow, temperature control and equipment longevity.

- Alkalinity: Similar to pH levels, low alkalinity often leads to corrosion, while high alkalinity can cause scale buildup.

- Temperature: Higher temperatures typically increase the rate of chemical reactions, which can promote scale formation or corrosion. Testing your equipment’s temperature and conductivity can help you maintain the proper temperatures for corrosion and scale prevention.

Monitoring Total Dissolved Solids (TDS) and Disinfectant Residuals

In addition to conductivity, you should also monitor your equipment’s TDS levels. TDS levels indicate how many dissolved ions are in your water, helping you manage blowdown in boilers and cooling towers. Managing blowdown is important for preventing sludge, scale and corrosion. It’s also necessary to test levels of disinfectants such as chlorine to control microbial growth.

Common Water Testing Methods and Tools

These common water testing methods and tools are essential for the water conditioning process:

Colorimetric Testing

Colorimetric testing uses photometers and comparators to indicate a specific substance’s concentration in your water. In this method, a reagent reacts with a sample to reveal the intensity of the sample’s color and indicate the substance’s concentration. Colorimetric testing is best for

quick, visual concentration estimations.

Titration

In the titration method, technicians use drop tests or burettes to gradually add a reagent to a substance until a color change occurs. The number of drops indicates the substance’s concentration in your water. This is an excellent way to monitor alkalinity or hardness. Titration kits are best for precise, quantitative measurements of concentrations.

Electrochemical Meters

Electrochemical meters are portable and can perform instant readings of these parameters:

- pH levels

- Conductivity

- Oxidation-reduction potential

Microbiological Testing

Microbiological testing involves culture-based methods such as dipslides to monitor microbial activity. This method is an excellent option for detecting and measuring microorganisms such as:

- Viruses

- Bacteria

- Fungi

Detecting potentially harmful microorganisms helps protect equipment such as pipelines and cooling towers from biofouling. It’s also vital for ensuring safe water in applications such as pharmaceuticals, food processing and beverage manufacturing.

Quality Test Kits for Precise, Dependable Results

Reliable test kits allow you to identify contaminants in your facility’s water and make informed decisions. The following water test kits use quality instruments and reagents to measure specific impurities:

Alkalinity

EndPoint ID® water alkalinity test kits measure levels of:

- Carbonate

- Bicarbonate

- OH alkalinity

These kits titrate your water sample with a basic acid solution, reaching a specified pH endpoint. pH 8.3 is the phenolphthalein alkalinity, and pH 4.6 is the total alkalinity.

Chelant

Measuring chelant levels is vital for controlling industrial water equipment with parts-per-million (ppm) ethylenediaminetetraacetic acid (EDTA) results. Chelant kits help prevent calcium, copper, magnesium and iron scaling by combining metal ions in a solution. Chelant test kits are excellent for applications involving industrial water treatment, sanitation and cleaning, and water and soil cleanup.

Chemical Oxygen Demand (COD)

COD kits test water samples for the level of oxygen necessary to oxidize organic matter present in the sample. This analytical, indirect method provides a quick, reliable measure of organic pollution, which is especially crucial in wastewater treatment applications. Higher organic compound concentrations result in higher COD measurements.

Chloride

Chloride test kits are important for boilers and cooling towers. A chloride test uses a silver nitrate solution to titrate your water sample with a chromate indicator. This helps control cycles in your industrial boiler and cooling tower. You can also opt for a mercuric nitrate titrant if you need lower-level detections.

Chlorine

If you use chlorine as a microorganism control agent in your water systems, it’s essential to measure total and free chlorine levels. Chlorine kills pathogens such as mold species, sulfate-reducing bacteria and slime-producing bacteria in various wastewaters and applications. You can use a chlorine test kit and choose from several chemistries to measure total and free chlorine levels.

Chlorine Dioxide

Chlorine dioxide testing is important for cooling towers. You can test concentration levels using accurate chlorine dioxide test kits that deliver results in ppm.

Hardness Test Kits

Scale can accumulate in your equipment as magnesium and calcium salts dissolve in your process waters. Hardness test kits detect trace levels of hardness starting at 0.3 ppm. EndPoint ID hardness test kits use EDTA chemistry to titrate magnesium and calcium levels.

Hydrogen Peroxide

Hydrogen peroxide test kits measure hydrogen peroxide concentration levels in ppm. You must test hydrogen peroxide levels in applications such as wastewater and wash water.

Orthophosphate

Orthophosphate helps prevent corrosion and control manganese and iron in water. Orthophosphate test kits include filtering equipment to use before testing for the most accurate results.

Phosphate

Phosphate test kits express results as ppm, hydroxyethylidene diphosphonic acid, or phosphonobutane tricarboxylic acid. You can also use a modified phosphate test kit for high alkaline waters or potential fluoride interference. For the greatest accuracy, verify your results with a Hach UV digestion kit.

Sulfite

Sulfite scavenges oxygen to prevent pitting and corrosion in water, and it’s common in boiler applications. Sulfite test kits offer a range of titrants and indicators to match your PPM detection requirements. For the most accurate results, it’s important to let each sample cool quickly and complete the test immediately.

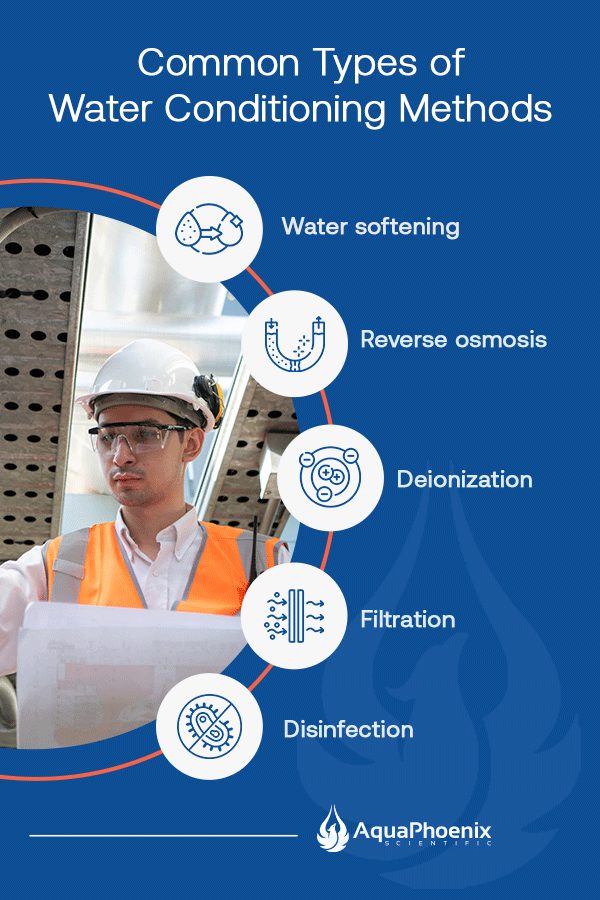

Common Types of Water Conditioning Methods

After testing your water, choosing the right treatment method is the next vital step in the water conditioning process. The following methods can help you reduce or eliminate contaminants and impurities in your water:

- Water softening: Water softening removes minerals such as magnesium and calcium to prevent scale buildup. This is crucial for equipment and components such as boilers and pipes.

- Reverse osmosis: Reverse osmosis uses high pressure to force water through a semipermeable membrane, which separates and removes contaminants. This method is an excellent option for removing salts, heavy metals and VOCs.

- Deionization: Deionization is a chemical treatment method that uses an ion exchange to eliminate dissolved impurities from water. This process passes water through a resin that exchanges charged ions for hydroxyl (OH-) ions and hydrogen (H+) ions. The OH- and H+ ions then combine to form pure water (H₂O). Deionization is an excellent treatment method if your facility’s processes involve heavy amounts of salts and minerals.

- Filtration: Filtration removes particles and suspended solids through straining, screening and clarification. This method is best for removing clay, sand and silt from your industrial water and protecting your equipment from corrosion.

- Disinfection: The disinfection water treatment method uses chlorination, ozone or UV systems to eliminate microbiological contaminants and prevent biological growth. This is the ideal method if you need to address disease-causing microorganisms such as parasites, viruses and bacteria.

How to Ensure Accuracy in Your Water Conditioning Processes

Remember these essential tips to ensure accurate results in your testing procedures:

- Use clean, appropriate instruments: Different testing kits may require different instruments. Use the correct instruments to avoid compromising your sample. It’s also important to clean and rinse your equipment before and after use to eliminate contaminants from previous tests.

- Calibrate equipment: Calibrate your equipment before each test to ensure instruments measure parameters with precision.

- Follow precise sampling procedures: Every test kit has specific sampling procedures. Follow all steps so you test the right sample type, size and temperature. Each sample should represent your entire system. You should always flush sample lines before collecting samples, and use the correct sample container for proper sizing. A testing kit may also include special instructions such as removing faucet screens or letting a sample sit overnight.

- Document results: Keep accurate records of your sampling dates, test results and corrective actions to track patterns and make informed decisions.

- Trust trained technicians: Only trained technicians should test your water. Ensure individuals performing tests have the appropriate training and experience with each method.

Enhance Your Water Testing Methods With AquaPhoenix Scientific’s Test Kits

Water testing is a vital part of the water conditioning process. Choosing the right system for testing and treatment is essential for protecting your equipment, increasing operational efficiency and maintaining your water’s safety. AquaPhoenix Scientific offers high-quality water testing kits, reagents and equipment, helping you achieve accurate results and make the most informed decisions for your water and equipment.

As a leading manufacturer of high-quality industrial water testing supplies, AquaPhoenix Scientific understands what you need to perform your job effectively. Browse our catalog of water testing products, or contact us to learn more about how we can enhance your water conditioning processes.